Author: Mark Yeager – Integrated Test & Measurement (itm), LLC, Rob Vickers – SixDOF Testing & Analysis, Inc.

Industry: Transportation

NI Products Used: iTestSystem, NI cDAQ-9135, NI 9234, NI 9229

Gallery:

In-Vehicle Vibration Testing Case Study | Vehicle Exhaust

The Challenge

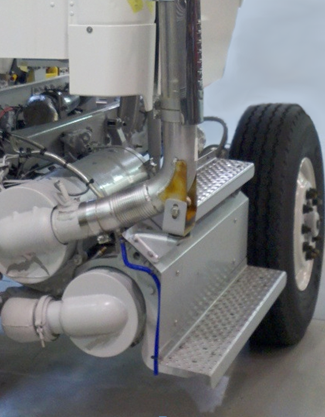

Creating a rugged and flexible in-vehicle testing solution to determine the vibration levels of an on-highway vocational vehicle’s exhaust system during operation.

“The stand-alone NI CompactDAQ controllers provide a high-performance and portable system for demanding in-vehicle testing applications. Our iTestSystem software, based on NI LabVIEW, combined with a NI CompactDAQ controller allows us to build flexible data logging systems faster than using traditional logging systems.” – Mark Yeager, Integrated Test & Measurement (itm), LLC

The Solution

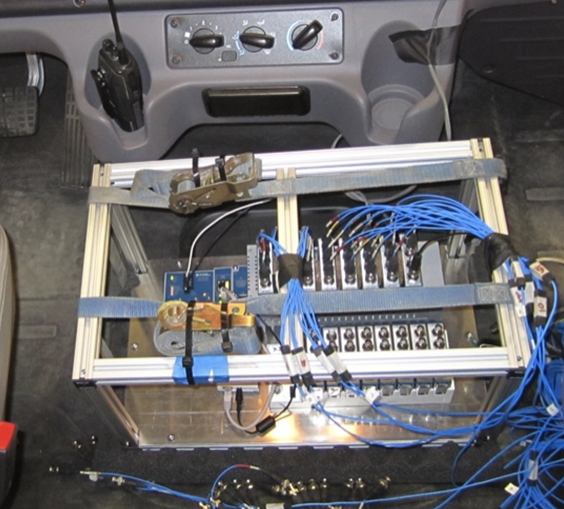

We chose the high-performance and rugged NI cDAQ-9135 CompactDAQ controller with NI C Series modules along with our LabVIEW-based data acquisition software, iTestSystem, to create a rugged, high-performance and portable exhaust test system for large vocational vehicles. Our solution provided a wireless interface to the NI CompactDAQ Controller to allow the operator remote control and monitoring of the embedded acquisition and logging system.

Transitioning from NI CompactDAQ to an NI CompactDAQ Controller

We’ve used USB and Ethernet-based NI CompactDAQ systems and our iTestSystem software, based on NI LabVIEW, for years to build high-performance data acquisition and test systems for our customers in the transportation and in-vehicle test system space. The NI CompactDAQ scontrollers provide a new line of portable and flexible hardware from National Instruments by combining an embedded processor with the modular NI CompactDAQ platform. Since these NI cDAQ-913x systems can be used with the same NI LabVIEW system design software, NI DAQmx driver and 50+ existing NI C Series modules, we can build new flexible logging solutions for our customers in a very short amount of time.

Designing a Flexible Logging Solution for Exhaust Testing

For this application, we chose the high-performance and rugged NI cDAQ-9135 CompactDAQ controller with seven NI 9234 accelerometer modules and one NI 9229 module to interface directly to the sensors we leveraged in this application. The cDAQ-9135 controller was bundled with a cellular network interface and packaged inside a rugged carrying case. For the sensors, we mounted 28 piezoelectric accelerometers to the exhaust system and connected them to the seven NI 9234 accelerometer modules. We also installed a magnetic pickup sensor and connected it to the simultaneous, differential NI 9229 analog module to determine rotational speed that would be used later in a post processing order analysis algorithm.

We leveraged the Windows Embedded Standard 7 OS running on the NI cDAQ-9135 to make the transition from using NI CompactDAQ USB-based systems connected to a laptop or PC a seamless process. We used our iTestSystem software, bbuilt with NI LabVIEW system design software, to stream data from staged events and operation directly to the NI cDAQ-9135’s non-volatile hard drive in a TDMS file format. We were able to control and monitor the data acquisition remotely via Remote Desktop by connecting the cDAQ-9135 to a Wi-Fi network using a cellular broadband modem and router with Wi-Fi.

After collecting data, all of the TDMS data files were transferred to a computer for post processing and analysis. The analysis for this project included calculating the overall vibration levels for each accelerometer using the order analysis plug-in for iTestSystem software that leverages the built-in analysis functions within NI LabVIEW. Additionally, with iTestSystem and TestView Plus, we were able to provide our customer with a professional report containing overall vibration levels and order analysis graphs that identified which sensor locations failed or met the design criteria.

The Advantage of our Vibration Test System

Leveraging an NI CompactDAQ controller and our iTestSystem software for this project was a huge success. Our customer was amazed at how quickly we were able to integrate new technologies including both NI and third party hardware and software. With this system, we were also able to reduce the overall cost of their test by reducing the manpower needed to perform the test and providing them with instantaneous feedback of the system functionality by utilizing new technologies. Our customer liked the system so much that instead of sending the system back to us, they redeployed the system onto another on highway vehicle to solve a different problem.

Author Information: For more information on this Case Study, building rugged measurement systems, our testing services or iTestSystem, contact: Mark Yeager – Integrated Test & Measurement (itm), LLC – mark.yeager@itestsystem.com

Related Links: